Original JAPANESE KNIVES - Chef's knives for highest demands

What are Japanese knives?

Only if all three of the following points are fulfilled are they originals:

Country of origin Japan: Only knives that were made or forged in Japan can be described as such.

Blade made of Japanese steel: Only if the steel used comes from Japan can it be a Japanese knife. However, the popular types of steel from Japan are often made into knives in other regions of the world.

Ground in Japan: The blade must have been ground or sharpened in Japan.

Caution: Japanese-style knives or similar paraphrases are misleading and are often intended to confuse or even deceive the buyer. Therefore, when buying, look carefully and pay attention to the details.

That's why Japanese knives are so special

The big difference between a European and a Japanese chef's knife lies in the blade structure. European chef's knives are usually stamped out, which makes the blade steel less hard. However, the hardness of a blade determines how sharp it can be ground.

JAPANESE CHEF'S KNIVES, HAND-FORGED AND EXTREMELY SHARP

European blades, on the other hand, have a clear disadvantage in terms of sharpening potential due to the softer steel. Their steel becomes blunt somewhat more quickly.

HAND FORGED JAPANESE KITCHEN KNIVES ARE DURABLE TOOLS

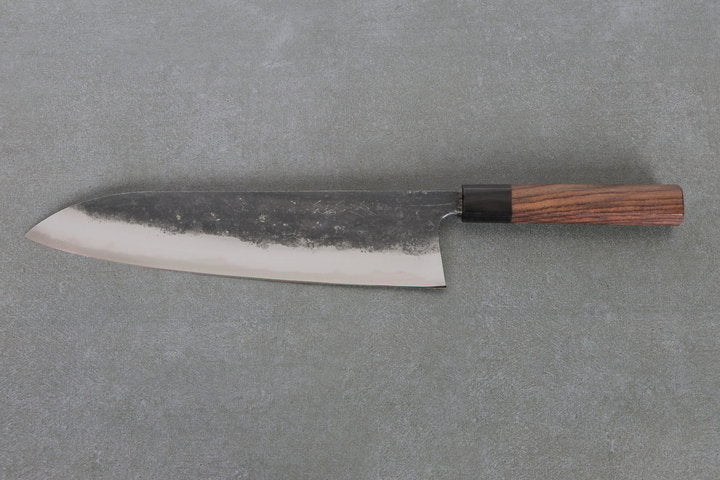

With one of our chef's knives, you acquire a durable product. The wooden handles, for example, are characteristic. Japanese handles are generally lighter than European handles, Japanese chef's knives are therefore much better balanced and basically more agile and precise. Japanese chef's knives with handles made of wood have the advantage that they acquire a better grip through moisture.

The sharpness also contributes to safety, as slipping off the cut material does not happen so quickly with a very sharp blade. Another difference is the craftsmanship behind the product.

Blacksmiths are experts in the field of steel processing. Here, different temperature ranges and processing temperatures have to be taken into account. These techniques are often kept as a secret, are very difficult to learn and hard to copy industrially - that is tradition!

JAPANESE KNIVES: GENUINE CRAFTSMANSHIP

Swords have been forged in Japan since the 15th century, the world-famous katanas. From this, the production of hand-forged knives has developed. Many traditional cutlers still make katanas, or at least are historically associated with them. The art of knifemaking has thus been perfected over centuries.

A hand-forged blade from Japan is a cultural asset that today has followers all over the world. Yet the products from the different forges can differ greatly. In the often small, family-run craft businesses (well-known forges include Aoki Hamono with the Sakai Takayuki product line, but there are also larger manufacturers such as Haiku, Tojiro), different philosophies have developed over the generations.

For example, there are companies that make robust blades designed for performance from classic steels. Other blacksmiths have optimised the wood for the handles and their forging technique to create cooking knives that are as light as possible. Still other smiths use their knowledge exclusively to produce special blade shapes, such as Damascus knives or Santoku knives.

Japanese chef's knives are not only popular for cultural reasons. In times of industrial mass production, they have unbeatable advantages and more than ever their raison d'être. This is due to several factors. The biggest factor, apart from the wooden handles, is the steel: Japanese knife steel is harder than knife steel used in this country. The blades are therefore harder and sharper.

STRUCTURE OF JAPANESE KNIFE BLADES

The blades have a 3-layer structure (this is different for damask knives). The hard core steel is surrounded on both sides by a protective sheath steel layer (often stainless steel). At the cutting edge, the core steel is ground free, and the transition from sheath steel to core steel is usually easy to see. Due to this structure, such kitchen knives are much more ergonomically balanced than the heavy and handle-heavy chef's knives of conventional European manufacturers. The weight distribution means that even intensive use hardly causes any signs of fatigue.

In addition to the various knife steels and forging techniques, different types of knives have also evolved over the centuries. Santoku knives and Damascus knives are particularly famous.

SANTOKU AND CO. - JAPANESE ALL-PURPOSE KNIVES

MOST FAMOUS JAPANESE KNIVES

The nakiri has established itself as a vegetable knife. This Japanese vegetable knife is characterised by its almost rectangular and relatively wide blades. Due to the small blade thickness, very precise cuts are possible with nakiris. The Nakiri is also suitable for chopping vegetables and herbs. The single-edged brother is called Usuba. Japanese Usuba chef's knives are rather unknown in Japan.

For smaller cuts, peeling and fruit, the petty is excellent. This is why it is sometimes called a paring knife or an office knife. The relatively short blades make this type of knife a handy chef's knife that is popular for delicate work where the blades are precisely guided. In addition to the Santoku knife, the Petty is often used as a small all-purpose knife in the kitchen. Herbs can also be cut well with such a short chef's knife.

For poultry, the Honesuki knife is the optimal Japanese knife. With the relatively stiff blades, poultry can be boned and poultry joints can also be cut (do not chop, a Honesuki is not a cleaver!). The narrow blade of the Honesuki knife can be guided precisely along bones so that clean pieces of meat can be cut off. The meat can then be cut directly for further processing.

There are also blade shapes that are specially designed for preparing fish and sushi. These include the sushi knife (yanagiba), sujihiki (ham knife), funayuki kiritsuke and deba. Especially for sashimi, the Yanagiba has a clear advantage because of its long, single-edged blade. The Deba can also cut bones and small fish bones and was designed for this purpose.

Japanese Chef's Knives - WHAT TO BUY

It is also important to bear in mind that prices vary greatly depending on the choice of steel, handle material and surface structure. A good chef's knife from Japan starts at around 130€. In this context, you should also consider how important appearance is to you. For simply designed models that function excellently are usually cheaper than very elaborately made kitchen knives, some of which are also bought as collector's items from the Land of the Rising Sun.

A basic decision should also be made regarding the steel. Here you have the choice between traditional and modern knife steels as well as hybrid knife steels. Traditional knife steels achieve very high degrees of hardness and sharpness. Modern knife steels are easier to care for because of their corrosion resistance, but they do not achieve the hardness levels and sharpening potential of traditional knife steels. There are also hybrid knife steels such as HAP40 and ATS-34 (we also stock items forged from this steel), which become extremely hard and sharp after machining, but still have very good corrosion resistance.

JAPANESE KNIFE STEELS - THE PERFECT CUT

Japanese knife steel is valued worldwide for its outstanding properties. Basically, Japanese knife steels differ in terms of hardness, sharpness, edge retention and corrosion resistance. Japanese chef's knives can have a hardness of up to 68 HRC, which is usually 8 HRC points higher than European chef's knives.

Traditional steels include Shirogami 1 (White #1), Shirogami 2 (White #2), Aogami Super, Aogami 1 (Blue #1) and Aogami 2 (Blue #2). These are also called paper steel. Paper steel blue or white is solely due to the packaging at the time of delivery. The advantage of these steel types is their very high hardness and sharpness. A well-sharpened Japanese knife with one of these traditional core steels will always beat a conventional Western knife in terms of sharpness and hardness. These traditional knife steels are characterised by a high carbon content. Accordingly, these steels are not stainless and must be well maintained.

More modern knife steels such as VG 10, AUS10 and Gin 3 offer the advantage that they are only slightly susceptible to rusting. It should be noted, however, that even a supposedly stainless steel from European manufacturers can corrode, e.g. through dishwasher cleaning or permanent moisture. The easy-care Japanese knife steels are more flexible and less porous compared to the carbon steels described above, but have a lower hardness.

Last but not least are the high-performance steels that combine the best of the carbon and stainless steel worlds: extreme hardness and sharpness combined with high rust resistance. These include HAP40, ATS-34 ZDP189. These knife steels are still relatively new on the market and are only just beginning their triumphal march. We have already tested these knife steels and are convinced that the advantages of these blades will become established.

HAP40 is a powder-metallurgical steel that reaches up to 68 HRC. At the same time, it is extremely durable - this Japanese knife steel keeps its sharpness 3 - 5 times longer than conventional knife steels! In addition, HAP40 knife steel is hardly susceptible to rust, which makes it an easy-care alternative to similarly hard steels. We have made HAP40 a focal point in our knife shop because of its outstanding quality and stock numerous items and series made from this material.

CARE INSTRUCTIONS FOR A LONG KNIFE LIFE

If you follow a few tips, you will enjoy using one of our items for many years. Our knife care tips do not only apply to Japanese blades, but can be used for all knives.

TIP 1 - CUTTING SURFACE:

Plastic pads or wooden boards are always preferable to very hard materials. Soft wood pads in particular ensure that the sharp cutting edge of the knife remains intact for longer.

TIP 2 - CLEANING:

A kitchen knife should never be cleaned in the dishwasher. The knife handles, which are often made of wood, can swell and the knife will rust more quickly. The salts and detergents in the dishwasher should therefore not come into contact with knives made by hand. It is best to clean your knife by hand after use with lukewarm water, a fine sponge or cloth and washing-up liquid. Dry the knife after rinsing!

TIP 3 - STORAGE:

Japanese knives should not be stored together with other knives, as there is a risk of damage. Wooden knife blocks, the supplied knife box or knife bags are recommended.

TIP 4 - SHARPENING:

Every knife blade will wear out over time due to its characteristics and will then need to be re-sharpened. Only water sharpening stones should be used for this. Alternatively, a sharpening service can be used.

JAPANESE KNIFE SHARPENING

Sharpening a Japanese knife is not complicated. With a little practice, you can achieve perfect results even without previous experience. Always use a whetstone, sharpening steels are not recommended. A water whetstone does not cost much and is very durable. The choice of whetstones depends on the degree of wear of the blade. We have extensively tested the whetstones we offer. The respective product descriptions of the articles show which whetstones or whetstone sets are best suited to which requirements.

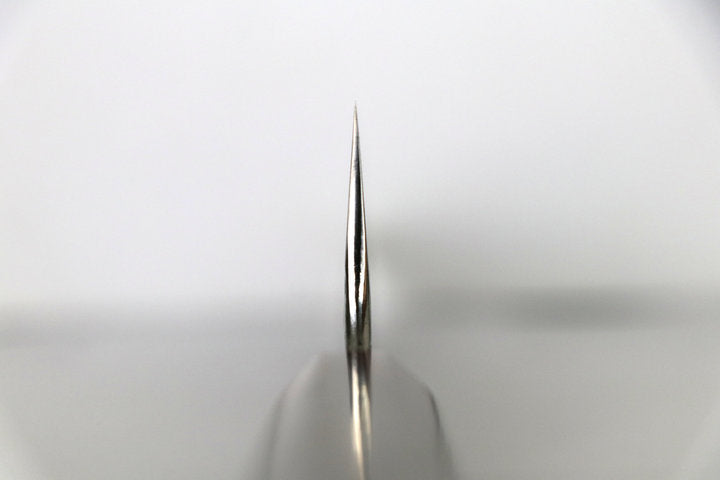

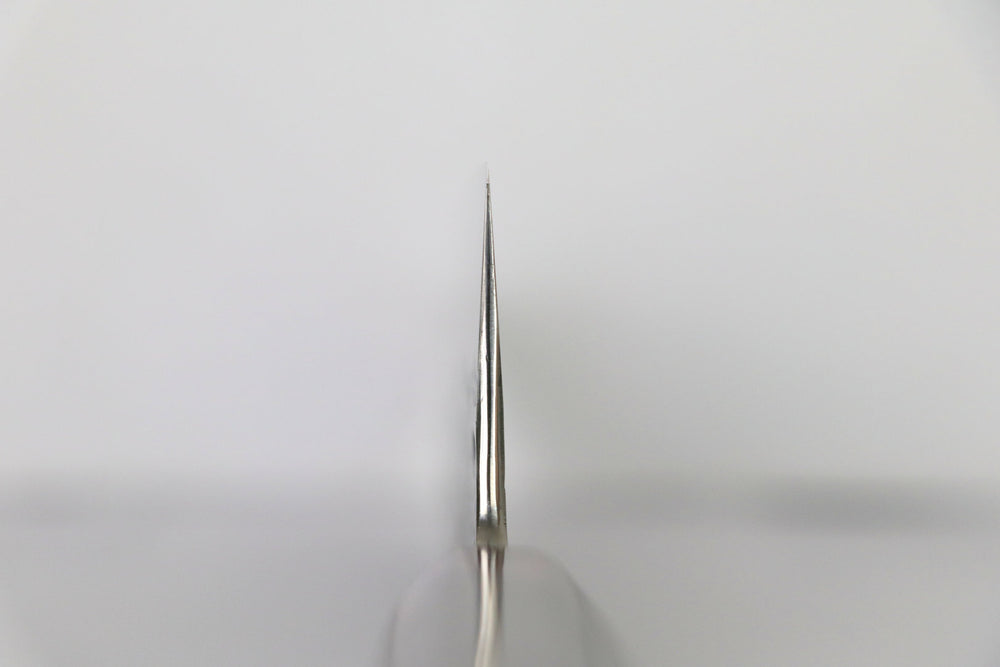

Japanese Knife Grinding Angle

There are various ways to sharpen Japanese chef's knives. Often the question arises, which angle is best. This question can be answered in two ways and depends on the desired use. If a knife is to be maximally sharp and the blade hardness is greater than 63 HRC, then 13 degrees is feasible. However, this makes the cutting core very thin. Therefore, chef's knives with an angle of 13 degrees and less often need to be resharpened with the whetstone.

Steels with less than 60 HRC should have a minimum angle of 15 degrees. Since these are mostly stainless steel knives or knives without carbon steel, the steel is tougher with less hardness. Grinding angles that are too small make the cutting core unstable and it deforms or breaks out.

So a middle ground must be found. If you want absolute sharpness, the angle can be smaller, but then you have to sharpen the knives more often with the whetstone. The greater the angle, the lower the sharpness, but the less regular knife care is required.

A sharpening steel is not recommended for Japanese chef's knives. A sharpening stone and a leather for honing are the right way to handle products of forging and such high quality.

Can you sharpen Japanese kitchen knives with a roller grinder?

Japanese knives are mostly made of carbon steel and the chrome content varies depending on the variant. This means that a wide range of properties can be covered. Chromium makes the steel less susceptible to corrosion, but chromium in the steel also affects the HRC value. VG 10 steel has more chromium than blue paper steel or white paper steel. In short, the harder a steel, the easier it can break. From 60 HRC, shocks can damage a knife, and from 63 HRC, this effect is even more pronounced. Therefore, one must be careful when sharpening these Japanese knives. Roller grinders usually have only two grits and the grind is predetermined by the geometry of the roller grinder. If the kitchen knife is now sharpened at 17 degrees, the Japanese chef's knife can break out at the edge. It must therefore be sharpened slowly and carefully with a certain amount of experience to avoid damage.

HOW TO FIND THE BEST JAPANESE KNIFE

Use the following five features to decide which kitchen knife is the best choice:HOW OFTEN DO I USE MY JAPANESE CHEF'S KNIFE?

If a kitchen knife is used frequently, the material is also subjected to corresponding stress, for example on the handle and blade. Accordingly, it is essential to pay attention to the quality of workmanship when buying a knife.

WHAT DO I USE MY JAPANESE HOCHO KNIFE FOR:

There are different types of knives depending on their purpose. Santoku knives, bunka and gyuto are mostly used as all-purpose knives. A special form for vegetables is the nakiri knife. For small cuts and for fruit and peeling work, the shorter pettys are used. If you mainly process fish, a funayuki or kiritsuke knife is a good choice. If you like to prepare sushi, you should take a look at our sushi knives and sujihiki knives.

SHARPNESS OF JAPANESE KNIVES:

The different Japanese knife steels have different sharpening potentials, keep their sharpness for different lengths of time and require different care. The most extreme sharpness can be achieved with the traditional carbon steels Shirogami and Aogami, as well as with the high-performance steels ATS-34 and HAP40. The steel grades AUS10, GIN3 and VG 10 have a lower sharpness potential, but are easier to maintain.

APPEARANCE OF THE KNIFE:

Ergonomics of the chef's knife:

Another decisive factor for choosing a kitchen knife is how safe it feels when processing food. This feeling is mainly influenced by the balance, the handle and the weight and size of the knife. When it comes to the handle, there are different shapes and finishes. Some customers prefer Japanese knives with natural handles without edges, others prefer octagonal handles. The size of a Japanese Hocho has a significant influence on how the chef's knife feels in the hand.

JAPAN KNIVES IN THE TEST - ALWAYS PERFECT RESULTS

Our Japanese kitchen knives are intended to show a large cross-section of the world of Japanese chef's knives. That is why we have different series in our range, each representing a different philosophy. We also have a wide range of steels available, from the traditional steels to the easy-care and more modern steels to innovative high-performance steels such as HAP40. Our range is complemented by suitable sharpening accessories for the kitchen knives.

Japanese knives and forges at Silverback Knives

Japanese chef's knives have special characteristics and combine tradition and craftsmanship. There is therefore a worldwide demand, which makes it difficult to attract a Japanese knifemaker and get their products on offer. Therefore, we have contacted the best master smiths from Japan in order to be able to offer their Japanese kitchen knives in Europe. This is how we managed to bring the Japanese craft with a long tradition to Europe.

Specimens from Matsubara are not only forged from beautiful design and craftsmanship, but also of the highest functionality. Since time immemorial, forging has been done in the traditional way in the ancient city of Omura City in southern Japan near Nagasaki, a craft that dates back 800 years. Mr Tanaka Kama Kogyo is an experienced fourth generation blacksmith and is widely known for his Japanese knives. For our customers at Silverback Knives, it is an honour to offer these products. Their elegant design and high functionality make Zeit Nakiri knives the ideal addition to the equipment of any kitchen.

Using Japanese chef's knives correctly - the perfect cut

There are various forms of these knives, as different properties are required. A Yanagiba is therefore used with a different cutting technique than a Deba. They are actually tools that should support the work in the kitchen. The best-known technique for cutting is to move the Japanese chef's knife through the food with little pressure by pulling and pushing movements. Professionals and skilled cooks can also use the cradle cut.

JAPAN KNIVES VS. WESTERN KNIVES

Not only Japanese knives are famous all over the world, but also Western knives - e.g. from Germany - enjoy a high reputation. It is clear that the respective knives originated from different cultures.

The Japanese are precision workers who want to have the perfectly fitting blade at hand for every purpose (e.g. nakiri vegetable knife, santoku knife, etc.), while Europe and North America traditionally produce versatile, rather heavier chef's knives.

Further differences between Japanese kitchen knives and their Western counterparts are explained in the following article.

JAPANESE CHEF'S KNIVES - THE KNIFE STEEL

In addition to the attractive appearance and the wide range of variants, a Japanese knife is known above all for one characteristic: The sharpness of the blades. The excellent sharpness of Japanese kitchen knives is due to the knife steel used. This is particularly hard due to its generally high carbon content and is used for the blade core. Japanese kitchen knives reach up to 68 HRC on the Rockwell scale. This value is significantly higher than that of conventional western knife steel.Anyone who cuts with a well-sharpened blade from Japan for the first time will ask themselves why they have spent their lives using comparatively blunt blades. Japanese kitchen knives are not only sharper than Western knives, they also retain their sharpness over a longer period of time.

In comparison, Western knives place more emphasis on robustness and ease of care. A German knife, for example, is made of a softer steel. This steel does not achieve the sharpness of a Japanese kitchen knife and also needs to be sharpened more often. On the other hand, a western knife has the advantage that it is easier to maintain. The lower carbon content in the steel ensures that the blade hardly rusts.

Japanese chef's knives are also much lighter than Western knives. In German knives, the steel often runs through the entire handle, which results in a correspondingly high weight. A heavier weight offers the advantage that the knife contributes a certain amount to the cutting work through gravity alone, but in principle a heavy knife will cause fatigue more quickly than a lighter one.

In addition, a well-sharpened Japanese chef's knife will cut through food so effortlessly that you don't need the added effect of the blade's gravity. Japan knives are designed for precision and balance. They are not meant to tire the chef, but to allow him or her to perform food cutting effortlessly and with great precision and safety.

THE CUT OF JAPANESE AND WESTERN KNIVES

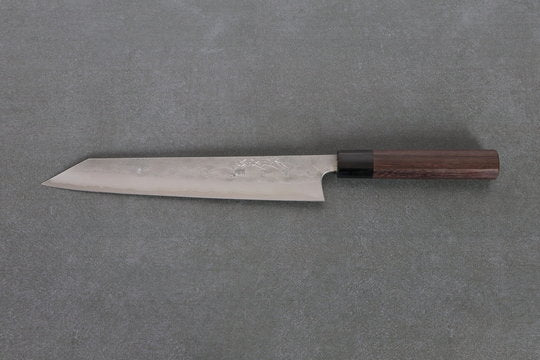

Due to the different properties of Japanese and Western knife steels, the respective knife blades are also ground differently. Western knives are usually ground on both sides, whereas Japanese knives are often ground on one side.

Due to the hardness of the knife steel used, the grinding angle can be smaller for knives from Japan than for Western knives based on softer types of steel. This applies to both one-sided and double-sided Japanese knives. This very fine grind makes extremely clean cuts possible, which is noticeable when preparing sushi or cutting vegetables and fruit, for example.

You will notice that the Japanese chef's knife, such as the Santoku knife, hardly damages the cells of the food, so that, for example, hardly any juice escapes from tomatoes or your eyes suddenly stop watering when cutting onions. Western knives are sharpened with larger angles because of the softer steel. They are therefore not as sharp as Japanese kitchen knives.

FAQs

The blades are made of hard steel and can therefore be sharpened. Blades made of soft steel cannot be made as sharp or the blade becomes blunt much faster than with Japanese chef's knives. Here you can find out everything about Knife steels.

The knives are often made of high-quality knife steel. In addition, the blades are more complex than industrially manufactured ones, which you can feel with every cut in the kitchen. Therefore, depending on the knife, several hours of manual work are involved.

In terms of sharpness and how long a Japanese blade stays sharp, this is definitely correct. If you are looking for a flexible and pliable blade, then rather not..

Japanese knives made of HAP40 steel are certainly one of them. Depending on the purpose and use, one must determine the type of knife for oneself. For us as long-time users, the HAP40 Bunka best Japanese knives der Welt.

Rarer than industrially produced blades. Depending on the degree of sharpness, however, it depends on one's own preferences. Professional chefs rather once a week and otherwise 1-2 times a quarter with regular use.

In principle with water abrasive stones. Here is the detailed Instruction knife grinding. However, there are alternative options, but care must be taken that the chosen abrasive and angle does not damage the knife blade during sharpening.

Aogami, Shirogami, Aogami Super should be ground at an angle of 15° - 17° degrees. HAP40 and ZDP189 between 13° and 17° degrees. VG10, AUS10, GIN3 and ATS34 between 16° - 19° degrees. These guide values are based on the optimum ratio of blade sharpness and how long the blade then remains sharp.

Wooden boards are ideal. Bamboo and softer types of wood are particularly gentle on the knife blade. But modern chopping boards made of certain plastics are also a good choice. It is important that the blade is not bent or even broken by hard surfaces.

For simple resharpening, a grit between 6000 and 10000 JIS is sufficient. Basic sharpening with 1000 - 3000 JIS and less than 1000 JIS rather only for repair work.

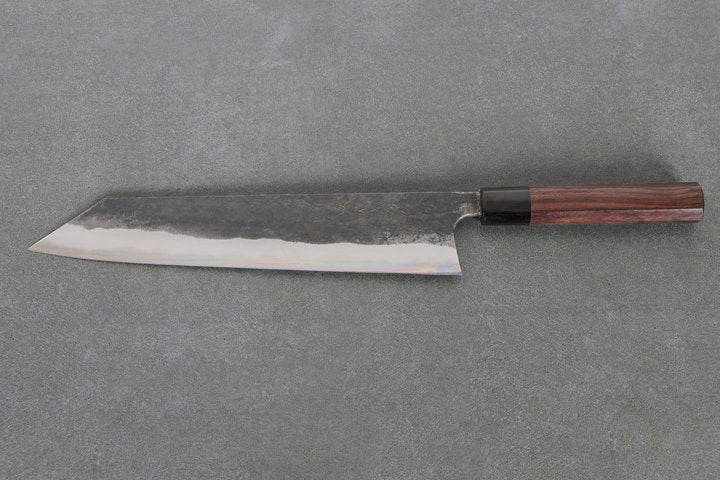

There are Tsuchime, Nashiji, Kurouchi and polished. Tsuchime blades have a hammered or rolled surface so that food can easily detach from the blade when cutting. Nashiji translates as pear skin and is also uneven. Kurouchi stands for charred surfaces, which are dark and protect against oxidation.